1. Agitator

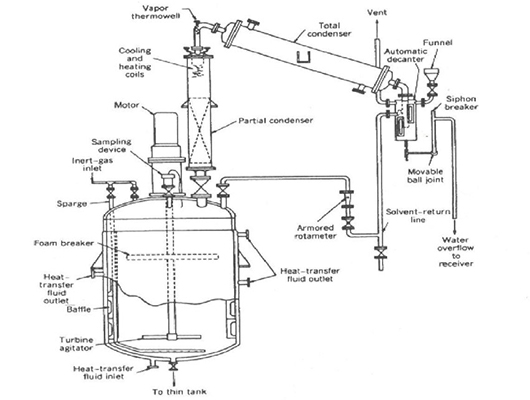

Function: Agitator is the core component of resin reactor, responsible for mixing the reaction materials evenly to ensure the uniformity and effectiveness of the reaction

Common Types:

- Screw-belt Agitator: Used for stirring high-viscosity materials.

- Frame Agitator: Suitable for low-viscosity materials.

- Anchor Agitator: Suitable for slurry or high-viscosity reaction materials.

2. Heating / Cooling System

Function: Heating system can control the temperature of the reaction to ensure that the reaction process is carried out at an appropriate temperature. The cooling system is used to control the temperature rise during the reaction process to avoid overheating or too fast reaction.

Accessories:

- Jacket Heating / Cooling Pipeline: Reaction temperature is adjusted by conveying hot water, steam or cooling medium through the jacket on the outer wall of the resin reactor.

- Coil: Used to provide more direct heat exchange in the resin reactor.

- Thermostat and Temperature Sensor: Real-time monitoring and adjustment of temperature.

3. Vacuum System

Function: Some resin reaction processes need to be carried out in a vacuum environment to avoid interference of moisture and oxygen in the air on the reaction.

Accessories:

- Vacuum Pump: Used to extract air from the resin reactor to create a vacuum state.

- Vacuum Gauge: Monitors the vacuum degree in the resin reactor to ensure the stability of the vacuum environment.

- Vacuum Pipeline and Valve: Connects the vacuum pump and reactor.

4. Condensation Reflux System

Function: Used to recover volatile solvents or other gases generated during the reaction process, ensure the effective use of raw materials, and avoid environmental pollution.

Accessories:

- Condenser: Cools the gas into liquid and refluxes it into the resin reactor.

- Cooling Water Circulation System: Helps the condenser work through the water cooling system.

- Reflux Pipeline: Used to transport condensate to the resin reactor.

Home

Home JCT

JCT  Feb 20,2025

Feb 20,2025

Why Is There A Demand For Epoxy Resin In The Market?

Why Is There A Demand For Epoxy Resin In The Market?