Why do Russian customers need acrylic resin production line equipment?

1. Demand market growth

Russia's coatings, paints, adhesives and plastic modification industries continue to develop, and the demand for acrylic resins has increased significantly, for example:

- Construction industry: There is a strong demand for coatings and sealants, and acrylic resins are one of the main raw materials.

- Automotive industry: Automative coatings and repair paints have a large demand for high-performance acrylic resins.

- Packaging and inks: The increase in applications in the field of food packaging coatings and inks has stimulated the demand for solvent-based and water-based acrylic resins.

2. Production cost advantage

Local production of acrylic resin can reduce tariffs and logistics costs, and companies can save a lot of money compared to directly importing finished resins. In addition, Russia is rich in energy resources and has relatively low production costs, which has the economic advantage of building localized acrylic resin production lines.

3. Russian companies hope to improve their technological autonomy

Some Russian chemical companies hope to master core resin synthesis technology, improve their competitiveness, and expand their international markey. Investing in adcanced acrylic resin production line can help companies master production processes and enhance their market competitiveness.

Main Equipments of Acrylic Resin Production Line

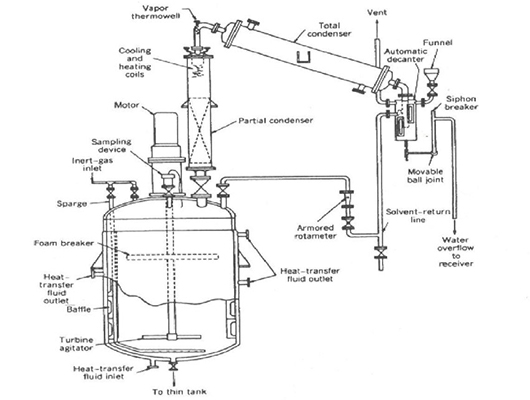

- Reactor: used for the polymerization of acrylic acid monomers, usually made of stainless steel and equipped with a jacket or coil heating / cooling system.

- Condenser: used to condense unreacted monomers, improve recovery rate and reduce pollution.

- Solvent recovery device: can reduce solvent loss and improve production efficiency.

- Vacuum system: used for degassing and controlling reaction pressure.

- Filtration system: removes impurities and ensures resin quality.

- Storage tank: stores finished resin for subsequent packaging or application.

Reactors sold to Russian customers for the production of acrylic resin will have the following special configurations:

1. Design adapted to low temperature environment

- High-efficiency Insulation Layer: Rock wool or polyurethane insulation layer is used to ensure that the reactor can maintain a stable temperature in a cold environment.

- Antifreeze Electric Heating System: Used to heat key pipes and valves to prevent low temperature from causing material solidification or equipment damage.

2. Corrosion-resistant and high-strength materials

Use 304/316 stainless steel to manufacture the reactor liner to enhance corrosion resistance.

The reactor body should have pressure resistance and high temperature resistance to adapt to high-temperature polymerization reaction processes.

3. Forced cooling system

Equipped with high-efficiency condenser and circulating cooling system, cooling water or cooling oil can be used to prevent the reaction temperature from being too high and affecting the quality of the resin.

Considering the problem of water resources freezing in some parts of Russia, ethylene glycol cooling system can be used to prevent the cooling medium from freezing.

4. Explosion-proof and safety design

Explosion-proof motors, control cabinets and sensors ensure production safety.

Automatic pressure relief valve and emergency shutdown system ensure automatic protection of the reactor under abnormal conditions.

5. Highly automated control system

Adopt PLC system to remotely monitor key parameters such as reaction temperature, pressure, stirring speed, etc.

DCS (distributed control system) can be optionally equipped to facilitate linkage control with other chemical production equipment to improve production efficiency.

Why choose JCT Machinery?

1. JCT is professional in chemical mixing equipment since 2006.

2. JCT's engineers have more than 25-year experiences in this field.

3. Nice business manager with profession engineers for every customer.

4. All equipments have 1 year warranty.

5. Provide glue/resin formula.

6. JCT's account can directly receive money from Russian customers, without the need for customers to pay extra fees for transfers from other countries

Home

Home JCT

JCT  Mar 31,2025

Mar 31,2025

Paint And Coating Production Line

Paint And Coating Production Line