Widely Applied and Expanding its Range Rapidly

Urea resin has found extensive applications across numerous industries, including building materials, home furnishings, plastics, electrical appliances, coatings, and more. This is attributed to its low cost, excellent adhesion, hardness, and water - resistance.

Product Features

- Wide Range of Applications

It can be applied in various industries such as the coating industry (including architectural coatings, automotive coatings, wood coatings, etc.), the adhesive field (covering paper, packaging, wood, flooring, etc.), ink (especially flexographic printing ink), textiles (improving fabric flexibility, wear resistance and water resistance) and electronic materials (such as electronic packaging materials, printed circuit boards, etc.), demonstrating strong versatility and adaptability.

-

Performance Optimization

In different application fields, it can play corresponding performance advantages targeted, helping to improve the quality and usage effect of corresponding products. For example, it can improve multiple fabric properties in the textile field and meet the usage requirements of relevant materials in the electronic materials field.

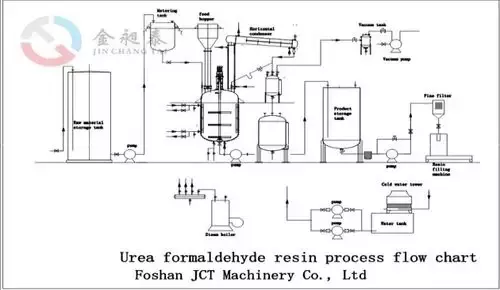

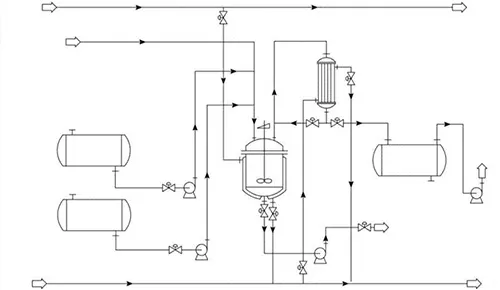

Production Line Equipment Configuration

- Cost - effective: Features low cost, making it an economical choice for various industries.

- Good adhesion: Exhibits excellent adhesion, which is crucial for its use as an adhesive in different applications.

- High hardness: Possesses high hardness, ensuring durability in products like plastics and coatings.

- Water - resistant: Shows good water - resistance, suitable for applications where moisture resistance is required.

- Precise production equipment: Equipped with a metering pump for accurate raw material measurement, a reactor as the core for chemical reactions, and a dehydration equipment to ensure product quality.

- Stable production process: Maintains stability through a cooling system controlling temperature, a concentrator for appropriate concentration, and a filtration system for impurity removal.

- Versatile applications: Applied in artificial board, coating, plastic, adhesive, electrical, agricultural, and wood - related industries due to its diverse properties.

- Good insulation: Has remarkable electrical insulation properties, making it suitable for electrical components and housings.

- Enhanced product properties: Can endow products like fiberboard with good strength and durability, and improve the aesthetics and durability of furniture coatings.

- Function - specific in different fields: Serves as a fertilizer binder to increase fertilizer density and stability, and as a wood antiseptic to enhance wood's durability and corrosion resistance.

Application Fields

Artificial board industry

- Particleboard, density board, plywood: Urea - formaldehyde resin is prevalently used as the primary adhesive in the production of artificial wood boards. Its strong adhesion and good water - resistance make it a top choice in the furniture and building materials sectors.

- Fiberboard: It is applied in the manufacturing of medium-density and high-density fiberboard, endowing them with good strength and durability.

Coatings and paints

- Waterproof coatings: Urea - formaldehyde resin can be blended with other components to create waterproof coatings. It is particularly effective in wood surface treatment, providing excellent adhesion and weather resistance.

- Furniture coatings: Used to produce glossy coatings on the surface of wooden furniture, enhancing both its aesthetics and durability.

Plastic industry

- Urea-formaldehyde plastics: As the end-product of urea - urea-formaldehyde resin, these plastics can be used to manufacture electrical housings, home appliance parts, hardware accessories, automotive interior parts, etc. They possess good hardness, heat resistance, and insulation properties.

- Films and veneers: Employed in the production of film or veneer materials, especially for the surface coating of paper and wood.

Adhesives

- Paper, textile, and leather bonding: Urea - formaldehyde resin is frequently used as an adhesive for bonding paper, textiles, leather, and various fabrics, especially in the production of packaging materials.

- Composite materials: It offers strong bonding capabilities as an adhesive in various composite materials.

Electrical and electronic industries

- Electrical insulation materials: Urea - formaldehyde resin has remarkable electrical insulation properties and is utilized to make various insulating components in electrical and electronic equipment, such as plugs and switches.

- Electrical housing: Due to its high hardness and stability, it is also used for manufacturing the housing of electrical equipment.

Agriculture and horticulture

- Fertilizer binder: As a binder for fertilizer particles, the urea-formaldehyde resin can effectively increase the density and stability of fertilizers, preventing particle breakage and dust generation.

Wood antiseptic

- Anticorrosive wood treatment: Urea - formaldehyde resin can be used for the anticorrosive treatment of wood, enhancing its durability and corrosion resistance, especially for outdoor applications.

ABOUT JCT

JCT Machinery was founded in 2006. Its business involves mechanical equipment design and manufacturing, intelligent control system research and development, engineering design and installation, etc. The main products include resin synthesis reaction production line, adhesive manufacturing production line, etc., which are widely used. They mainly serve and are used in the fields of fine chemicals, coatings, adhesives, and other fields.

JCT's equipment and production lines have many Patents and areCE-certified. Its customers are spread over more than 30 countries and regions around the world and have been widely recognized and supported by many large and small companies at home and abroad.

JCT has an independent office and factory in Foshan, Guangdong, less than 1 hour's drive from Guangzhou Baiyun International Airport and Guangzhou South High-speed Railway Station. Customers are welcome to come for a face-to-face interview. JCT's sales and engineers will be very willing to have detailed technical communication and discuss optimization technical solutions with you.

FAQ

Are you a trading company or a manufacturer?

Can you send the formula for the products we want to make?

Can you send the detailed drawings of the machine to us before we place an order?