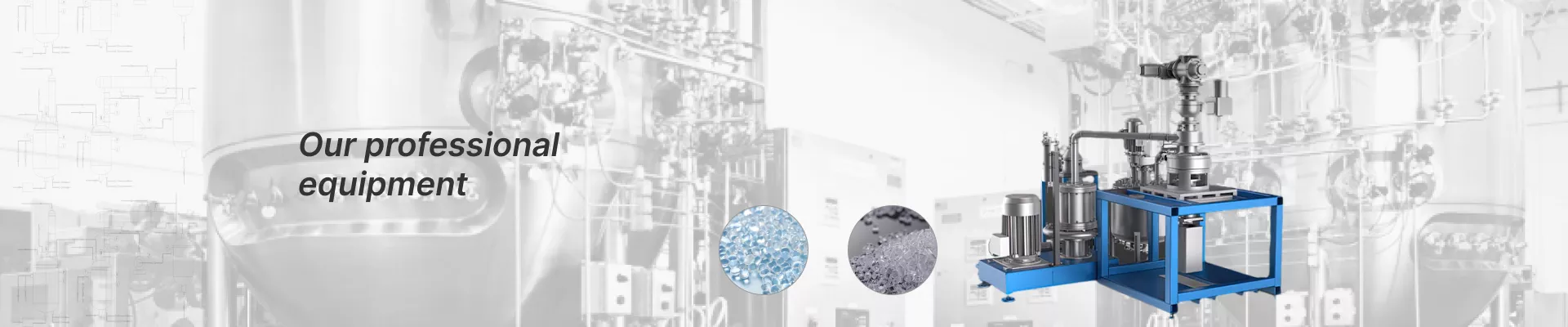

| Equipment | Main Function |

| Reactor | Carry out phenolic polycondensation reaction, control temperature and pressure. |

| Condenser | Recover water generated during the reaction to improve reaction efficiency. |

| Vacuum Dehydration System | Remove water from the system to improve resin purity. |

| Stirring Device | Ensure uniform mixing of materials and speed up reaction speed. |

| Cooling System | Cool down to a suitable storage or packaging temperature. |

| Storage Tank | Store finished resin for easy packaging and transportation. |

| Filtration System | Filter impurities to improve resin quality. |

| PLC | Monitor and control the entire production process to improve stability and safety. |

1. Polycondensation Reaction

Addition polycondensation reaction is carried out in the reactor, and the reaction conditions depend on the type of catalyst:

Water is generated during the reaction and needs to be recovered and discharged through the condenser.

2. Dehydration and Modulation

After the reaction is completed, the water is removed through the vacuum system to concentrate the resin. Plasticizers or diluents are added to adjust the viscosity of the resin.

3. Cooling and Curing

After the reaction, phenolic resin needs to be cooled in the cooling system to control the curing speed. Some products can be directly cooled and packaged, or further processes into powder, flakes or solutions.

1. Automatic Control

PLC control system is used to accurately control parameters such as temperature, pressure, stirring speed, etc. to ensure stable product quality. Remote monitoring function reduces manual intervention and improves production efficiency.

2. Environmental Emission Treatment

Formaldehyde gas and wastewater will be released during the production process. Phenolic resin production line needs to be equipped with tail gas treatment equipment and sewage treatment system to comply with environmental protection regulations. A closed reactor is used to reduce harmful gas emissions and protect the safety of operators.

3. High-efficiency and Energy-saving Design

High-efficiency heat exchange system is used to increase reaction rate and reduce energy consumption. Condenser design is optimized to maximize the recovery of by-products and reduce raw material loss.

4. Multi-purpose Compatibility

Phenolic resin production line can be applied to different types of phenolic resin (such as liquid, solid and modified). Thermosetting or thermoplastic phenolic resins can be produced by adjusting different catalysts.

Phenolic resin is widely used in the following industries: