Widely Applied and Expanding its Range Rapidly

High - efficiency dispersion system with variable - frequency speed - regulated high - speed disperser and optional one - machine double - cylinder disperser; tandem horizontal sand mill meeting fineness requirements at once, and options for color paste grinding; paint mixing system applicable to high and low viscosity products and capable of producing varnish; flexible filter selection; filling machine with multiple options for production flexibility; single - layer or three - layer operating platform reducing pipeline residue and power transmission energy consumption.

Product Features

- Dispersion system: The dispersion system uses a high - speed disperser with variable - frequency speed regulation, which offers high efficiency. Additionally, a one - machine double - cylinder disperser can be chosen. This type of disperser saves space and is easy to operate with electric rotation.

- Grinding system: The grinding system adopts a tandem horizontal sand mill, which can meet the fineness requirements of the oil - based paint at one time. For color paste grinding, a basket grinder or a pin - type horizontal sand mill can be selected.

- Paint mixing system: The paint mixing system uses a mixing kettle. It can be applied to both high - and low - viscosity products and is also capable of producing varnish.

- Filter: As mentioned before, the filter comes in two types, bag - type and vibration - type, allowing users to make choices based on the product characteristics.

- Filling machine: With the option of fully automatic or semi - automatic, and various packaging specifications, the filling machine provides flexibility in production.

- Operating platform: The operating platform can be either single - layer or three - layer. In the three - layer design, the dispersion equipment is placed on the top layer, the grinding equipment on the second layer, and the paint mixing equipment on the third layer. This top - down process can effectively reduce the residue in the pipeline and lower the energy consumption of power transmission. The filtering and filling devices are located at the bottom layer for easy transportation.

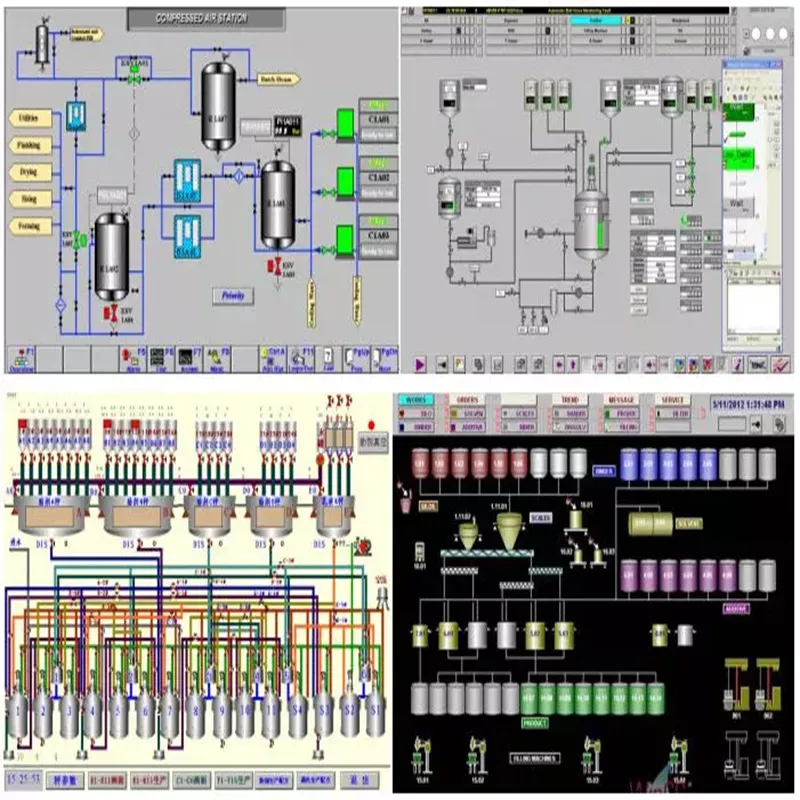

Production Line Equipment Configuration

- High speed disperser: It is a crucial device for evenly dispersing various raw materials in the oil - based paint production process. It helps to ensure the uniformity of the paint components.

- Horizontal sand mill: Responsible for the grinding and refinement of the paint, making the particles in the paint finer and improving the overall quality of the oil - based paint.

- Vacuum system: Used to create a vacuum environment during the production process, which can help remove air bubbles and impurities in the paint, thus improving the paint's performance.

- Paint mixing kettle: Serves as a container for thoroughly mixing different components of the oil - based paint to achieve the desired paint properties. It can be applied to products with different viscosities.

- Filter: Available in bag - type and vibration - type, which can be selected according to the specific requirements of the product. It filters out impurities in the paint to ensure the purity of the final product.

- Paint filling machine: There are two options, fully automatic and semi - automatic, with a variety of packaging specifications to meet different production needs.

Application Fields

- Wood protection: Oil - based paint provides excellent protection for wood. It can prevent wood from deforming, cracking, or rotting due to exposure to moisture or sunlight. It is commonly used for coating furniture, floors, and outdoor wood structures.

- Metal protection: When applied to metal surfaces, oil - based paint can effectively prevent rust. It is suitable for various metal products, such as steel and aluminum alloy.

- Construction and engineering: Oil - based paint is widely used for the surface protection of buildings, bridges, pipelines, and mechanical equipment, especially for long - term use in outdoor environments or harsh conditions.

ABOUT JCT

JCT Machinery was founded in 2006. Its business involves mechanical equipment design and manufacturing, intelligent control system research and development, engineering design and installation, etc. The main products include resin synthesis reaction production line, adhesive manufacturing production line, etc., which are widely used. They mainly serve and are used in the fields of fine chemicals, coatings, adhesives, and other fields.

JCT's equipment and production lines have many Patents and areCE-certified. Its customers are spread over more than 30 countries and regions around the world and have been widely recognized and supported by many large and small companies at home and abroad.

JCT has an independent office and factory in Foshan, Guangdong, less than 1 hour's drive from Guangzhou Baiyun International Airport and Guangzhou South High-speed Railway Station. Customers are welcome to come for a face-to-face interview. JCT's sales and engineers will be very willing to have detailed technical communication and discuss optimization technical solutions with you.

FAQ

Are you a trading company or a manufacturer?

Can you send the formula for the products we want to make?

Can you send the detailed drawings of the machine to us before we place an order?