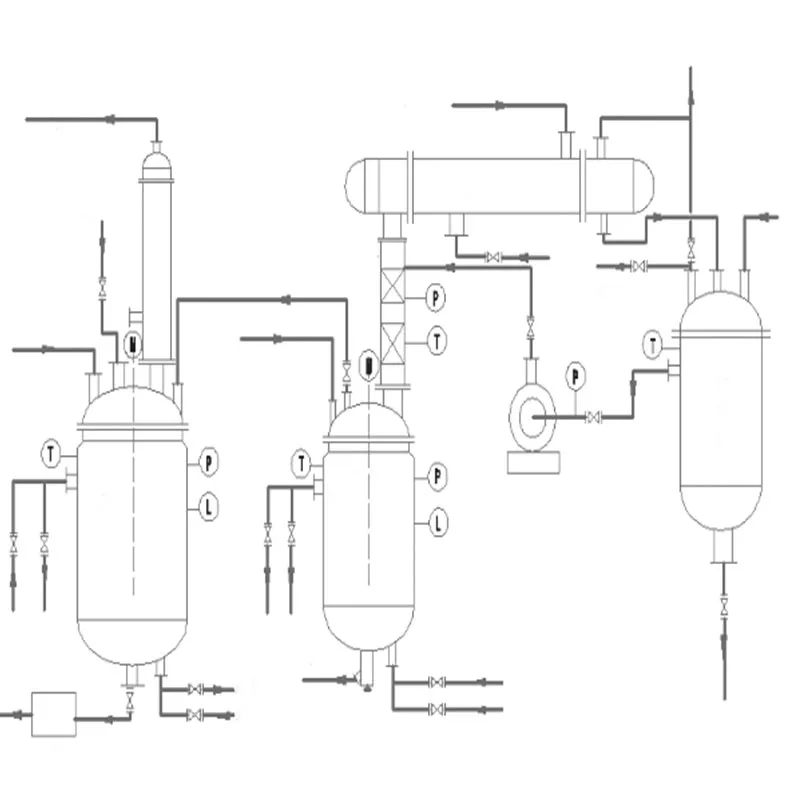

Alkyd resin production line covers multiple links including raw material storage, batching, polymerization reaction, dehydration, viscosity adjustment, cooling, packaging, etc. The production process requires precise control of reaction temperature, time, and raw material ratio to ensure the consistency and stability of product quality.

Alkyd Resin Production Line Capacity Selection

| 500kg/batch | 1000kg/batch | 2000kg/batch | 3000kg/batch |

| 4000kg/batch | 5000kg/batch | 6000kg/batch | 8000kg/batch |

| 10000kg/batch | 12000kg/batch | 15000kg/batch | 18000kg/batch |

| 20000kg/batch | 25000kg/batch | 30000kg/batch | |

| Can be designed according to customers’ requirements. | |||

Alkyd Resin Production Line Equipment Configuration

| Raw material storage tank | Metering tank | Polymerizing reactor |

| Fractionating colume | Condenser | Oil-water separator |

| Dilute reactor | Finished product storage tank | Net plate filter |

| Resin filling machine | Heating equipment | Cooling equipment |

| Vacuum equipment | Nitrogen generator | Material conveying equipment |

1. Coatings: used to make various paints, primers, topcoats, automotive coatings, etc., with good adhesion and weather resistance.

2 . Inks: used to produce printing inks, especially for printing on metal and plastic surfaces.

3.Adhesives: used for bonding materials such as paper and wood.

4.Anti-corrosion materials: used to produce anti-corrosion coatings and anti-corrosion layers, widely used in construction, shipbuilder, ding, and other field s.

5.Plastics and composite materials: used as a base resin, combined with other materials such as glass fiber, to produce composite materials for ships, automobiles, construction, and other fields.

JCT Machinery was founded in 2006. Its business involves mechanical equipment design and manufacturing, intelligent control system research and development, engineering design and installation, etc. The main products include resin synthesis reaction production line, adhesive manufacturing production line, etc., which are widely used. They mainly serve and are used in the fields of fine chemicals, coatings, adhesives, and other fields.

JCT's equipment and production lines have many Patents and areCE-certified. Its customers are spread over more than 30 countries and regions around the world and have been widely recognized and supported by many large and small companies at home and abroad.

JCT has an independent office and factory in Foshan, Guangdong, less than 1 hour's drive from Guangzhou Baiyun International Airport and Guangzhou South High-speed Railway Station. Customers are welcome to come for a face-to-face interview. JCT's sales and engineers will be very willing to have detailed technical communication and discuss optimization technical solutions with you.

Are you a trading company or a manufacturer?

We are a factory.

Can you send the formula for the products we want to make?

Our machines can be used for many kinds of product making, such as Resin, Paint, Adhesive, Cosmetic, Food, Cand chemicals. These products have many kinds, so we can't know all the formulas and technologies. We can assist you in finding the raw material list you need, and after you place an order with us, we can help you to find the formula and technology, there will be engineers to teach you how to make the product, and the cost will be on your account.

Can you send the detailed drawings of the machine to us before we place an order?

We can send you a draft drawing of the machines. After you place the order and pay the deposit, our engineer will design the specific Tectech technical parameters for you and send you the detailed drawings. Once you confirm without questions, we will put it into production.